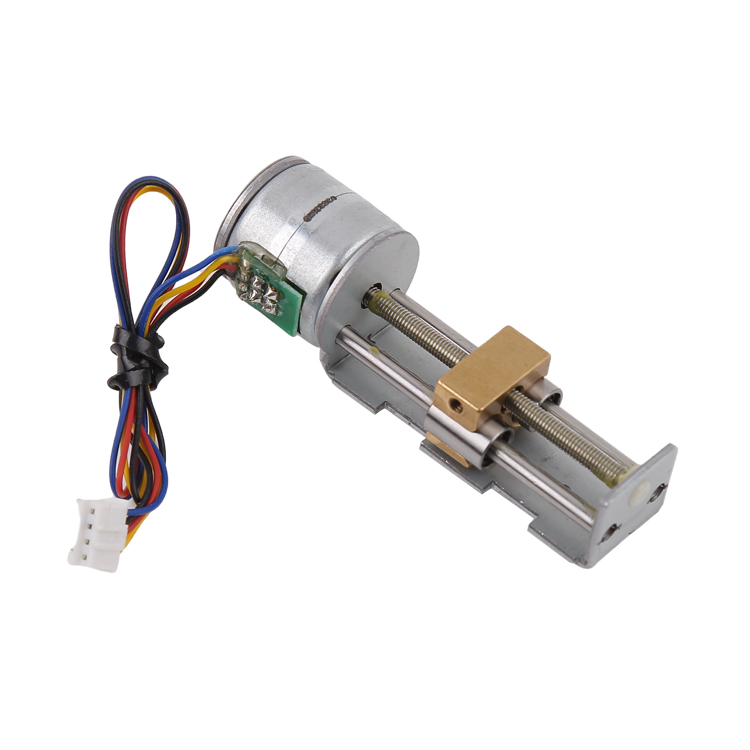

20mm ਵਿਆਸ ਵਾਲੀ ਉੱਚ ਸ਼ੁੱਧਤਾ ਵਾਲੀ ਲੀਨੀਅਰ ਸਟੈਪਰ ਮੋਟਰ M3 ਲੀਡ ਸਕ੍ਰੂ ਪਿੱਤਲ ਸਲਾਈਡਰ 1.2KG ਥ੍ਰਸਟ ਦੇ ਨਾਲ

ਵੇਰਵਾ

ਇਹ 20mm ਵਿਆਸ ਵਾਲੀ ਸਥਾਈ ਚੁੰਬਕ ਸਟੈਪਰ ਮੋਟਰ ਹੈ ਜਿਸ ਵਿੱਚ ਪਿੱਤਲ ਦਾ ਸਲਾਈਡਰ ਹੈ।

ਪਿੱਤਲ ਦਾ ਸਲਾਈਡਰ CNC ਤੋਂ ਬਣਾਇਆ ਗਿਆ ਹੈ ਅਤੇ ਇਸ ਵਿੱਚ ਮਜ਼ਬੂਤ ਸਹਾਰਾ ਪ੍ਰਦਾਨ ਕਰਨ ਲਈ ਡਬਲ ਲੀਨੀਅਰ ਬੇਅਰਿੰਗ ਹੈ।

ਸਲਾਈਡਰ ਦਾ ਜ਼ੋਰ 1~1.2 KG(10~12N) ਹੈ, ਅਤੇ ਜ਼ੋਰ ਮੋਟਰ ਦੇ ਲੀਡ ਪੇਚ ਦੀ ਪਿੱਚ, ਡਰਾਈਵਿੰਗ ਵੋਲਟੇਜ ਅਤੇ ਡਰਾਈਵਿੰਗ ਬਾਰੰਬਾਰਤਾ ਨਾਲ ਸੰਬੰਧਿਤ ਹੈ।

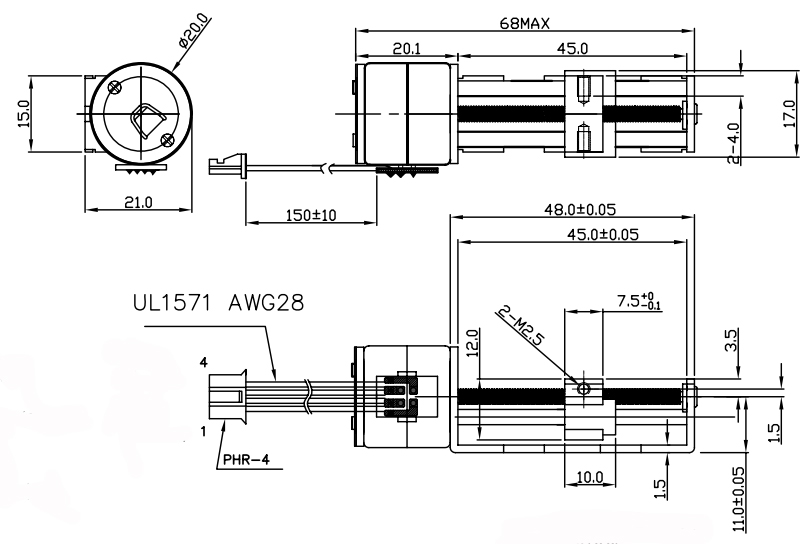

ਇਸ ਮੋਟਰ 'ਤੇ ਇੱਕ M3*0.5mm ਪਿੱਚ ਲੀਡ ਪੇਚ ਵਰਤਿਆ ਗਿਆ ਹੈ।

ਜਦੋਂ ਡਰਾਈਵਿੰਗ ਵੋਲਟੇਜ ਵੱਧ ਜਾਂਦਾ ਹੈ, ਅਤੇ ਡਰਾਈਵਿੰਗ ਫ੍ਰੀਕੁਐਂਸੀ ਘੱਟ ਜਾਂਦੀ ਹੈ, ਤਾਂ ਸਲਾਈਡਰ ਦਾ ਟਾਰਕ ਵੱਡਾ ਹੋਵੇਗਾ।

ਮੋਟਰ ਦਾ ਸਟ੍ਰੋਕ (ਯਾਤਰਾ ਦੀ ਦੂਰੀ) 35 ਮਿਲੀਮੀਟਰ ਹੈ, ਜੇਕਰ ਗਾਹਕ ਛੋਟਾ ਆਕਾਰ ਚਾਹੁੰਦੇ ਹਨ ਤਾਂ ਸਾਡੇ ਕੋਲ ਵਿਕਲਪਾਂ ਲਈ 21 ਮਿਲੀਮੀਟਰ ਅਤੇ 63 ਮਿਲੀਮੀਟਰ ਸਟ੍ਰੋਕ ਵੀ ਹਨ।

ਮੋਟਰ ਦਾ ਕਨੈਕਟਰ P1.25mm ਪਿੱਚ, 4 ਪਿੰਨ ਕਨੈਕਟਰ ਹੈ। ਜੇਕਰ ਗਾਹਕਾਂ ਨੂੰ ਹੋਰ ਪਿੱਚ ਕਨੈਕਟਰਾਂ ਦੀ ਲੋੜ ਹੁੰਦੀ ਹੈ ਤਾਂ ਅਸੀਂ ਇਸਨੂੰ ਹੋਰ ਕਨੈਕਟਰ ਕਿਸਮ ਵਿੱਚ ਅਨੁਕੂਲਿਤ ਅਤੇ ਬਦਲ ਸਕਦੇ ਹਾਂ।

ਪੈਰਾਮੀਟਰ

| ਮਾਡਲ ਨੰ. | SM20-35L-T ਲਈ ਖਰੀਦਦਾਰੀ |

| ਡਰਾਈਵਿੰਗ ਵੋਲਟੇਜ | 12V ਡੀ.ਸੀ. |

| ਕੋਇਲ ਪ੍ਰਤੀਰੋਧ | 20Ω±10%/ਪੜਾਅ |

| ਪੜਾਅ ਦੀ ਗਿਣਤੀ | 2 ਪੜਾਅ (ਬਾਈਪੋਲਰ) |

| ਕਦਮ ਕੋਣ | 18°/ਕਦਮ |

| ਜ਼ੋਰ | 1~1.2 ਕਿਲੋਗ੍ਰਾਮ |

| ਸਟਰੋਕ | 35 ਮਿਲੀਮੀਟਰ |

| ਲੀਡ ਪੇਚ | ਐਮ3*0.5ਪੀ |

| ਕਦਮ ਦੀ ਲੰਬਾਈ | 0.025 ਮਿਲੀਮੀਟਰ |

| ਉਤੇਜਨਾ ਵਿਧੀ | 2-2 ਪੜਾਅ ਉਤੇਜਨਾ |

| ਡਰਾਈਵ ਮੋਡ | ਬਾਈਪੋਲਰ ਡਰਾਈਵ |

| ਇਨਸੂਲੇਸ਼ਨ ਕਲਾਸ | ਕੋਇਲਾਂ ਲਈ ਕਲਾਸ e |

| ਓਪਰੇਟਿੰਗ ਤਾਪਮਾਨ ਸੀਮਾ | -0~+55℃ |

ਕਸਟਮ ਕਿਸਮ ਹਵਾਲਾ ਉਦਾਹਰਨ

ਡਿਜ਼ਾਈਨ ਡਰਾਇੰਗ

ਲੀਨੀਅਰ ਸਟੈਪਰ ਮੋਟਰਾਂ ਬਾਰੇ

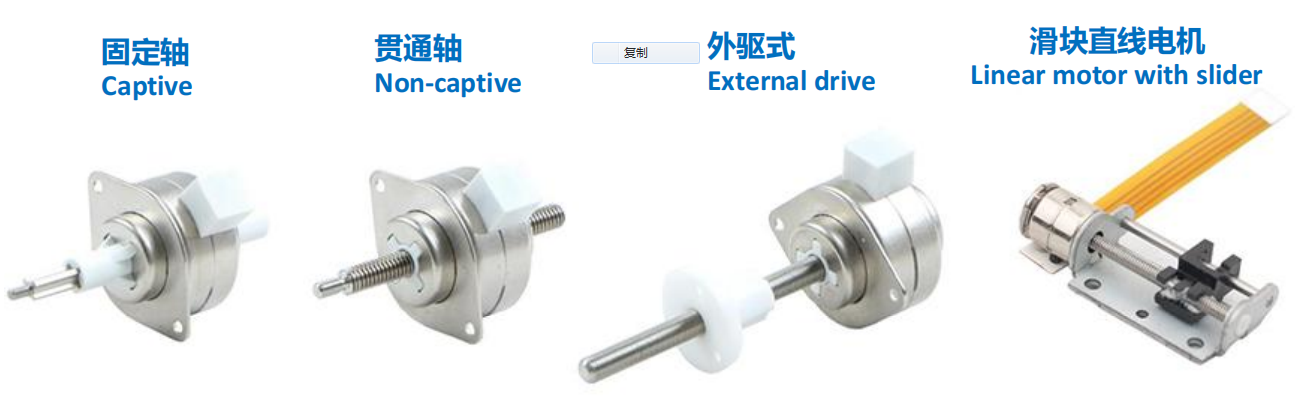

ਇੱਕ ਲੀਨੀਅਰ ਸਟੈਪਰ ਮੋਟਰ ਵਿੱਚ ਰੋਟੇਸ਼ਨ ਮੂਵਮੈਂਟ ਨੂੰ ਲੀਨੀਅਰ ਮੂਵਮੈਂਟ ਵਿੱਚ ਬਦਲਣ ਲਈ ਲੀਡ ਸਕ੍ਰੂ ਹੁੰਦਾ ਹੈ। ਲੀਡ ਸਕ੍ਰੂ ਵਾਲੀਆਂ ਸਟੈਪਰ ਮੋਟਰਾਂ ਨੂੰ ਲੀਨੀਅਰ ਸਟੈਪਰ ਮੋਟਰ ਮੰਨਿਆ ਜਾ ਸਕਦਾ ਹੈ।

ਇੱਕ ਸਲਾਈਡਰ ਲੀਨੀਅਰ ਸਟੈਪਰ ਮੋਟਰ ਵਿੱਚ ਇੱਕ ਬਰੈਕਟ ਹੁੰਦਾ ਹੈ, ਸਲਾਈਡਰ ਹੁੰਦਾ ਹੈ, ਅਤੇ ਸਹਾਇਕ ਰਾਡਾਂ ਨੂੰ ਬਾਹਰੀ ਡਰਾਈਵ ਲੀਨੀਅਰ ਮੋਟਰ ਦੇ ਡਿਜ਼ਾਈਨ ਦੇ ਆਧਾਰ 'ਤੇ ਜੋੜਿਆ ਜਾਂਦਾ ਹੈ। ਕਿਉਂਕਿ ਸਹਾਇਕ ਰਾਡਾਂ ਸਲਾਈਡਰ ਲਈ ਰੋਟੇਸ਼ਨ-ਰੋਟੇਸ਼ਨ ਵਿਧੀ ਪ੍ਰਦਾਨ ਕਰਦੀਆਂ ਹਨ, ਸਲਾਈਡਰ ਸਿਰਫ਼ ਲੀਨੀਅਰ ਗਤੀ ਹੀ ਕਰ ਸਕਦਾ ਹੈ।

ਲੀਡ ਪੇਚ ਦਾ ਲੀਡ ਇਸਦੀ ਪਿੱਚ ਦੇ ਬਰਾਬਰ ਹੁੰਦਾ ਹੈ, ਅਤੇ ਜਦੋਂ ਮੋਟਰ ਘੁੰਮਦੀ ਹੈ ਤਾਂ ਇੱਕ ਵਾਰੀ ਸਲਾਈਡਰ ਦੂਰੀ ਦੀ ਬਿਲਕੁਲ ਇੱਕ ਪਿੱਚ ਨੂੰ ਹਿਲਾਉਂਦਾ ਹੈ।

ਉਦਾਹਰਨ ਲਈ, ਜੇਕਰ ਮੋਟਰ ਦਾ ਸਟੈਪ ਐਂਗਲ 18° ਹੈ, ਤਾਂ ਇਸਦਾ ਮਤਲਬ ਹੈ ਕਿ ਇਸਨੂੰ ਇੱਕ ਮੋੜ ਘੁੰਮਾਉਣ ਲਈ 20 ਕਦਮ ਲੱਗਦੇ ਹਨ। ਜੇਕਰ ਲੀਡ ਪੇਚ M3*0.5P ਹੈ, ਪਿੱਚ 0.5mm ਹੈ, ਸਲਾਈਡਰ ਹਰੇਕ ਘੁੰਮਣ ਲਈ 0.5mm ਮੂਵ ਕਰਦਾ ਹੈ।

ਮੋਟਰ ਦੀ ਸਟੈੱਪ ਲੰਬਾਈ 0.5/20=0.025mm ਹੈ। ਇਸਦਾ ਮਤਲਬ ਹੈ ਕਿ ਜਦੋਂ ਮੋਟਰ ਇੱਕ ਕਦਮ ਚੁੱਕਦੀ ਹੈ, ਤਾਂ ਪੇਚ/ਸਲਾਈਡਰ ਦੀ ਰੇਖਿਕ ਗਤੀ 0.025mm ਹੁੰਦੀ ਹੈ। ਇੱਕੋ ਵਿਆਸ ਅਤੇ ਟਾਰਕ ਵਾਲੀਆਂ ਮੋਟਰਾਂ ਲਈ, ਇਸਦੀ ਸਟੈੱਪ ਲੰਬਾਈ ਜਿੰਨੀ ਲੰਬੀ ਹੋਵੇਗੀ, ਇਸਦੀ ਰੇਖਿਕ ਗਤੀ ਤੇਜ਼ ਹੋਵੇਗੀ, ਪਰ ਉਸੇ ਸਮੇਂ ਘੱਟ ਥ੍ਰਸਟ ਹੋਵੇਗਾ।

ਲੀਨੀਅਰ ਸਟੈਪਰ ਮੋਟਰ ਕਿਸਮ

ਐਪਲੀਕੇਸ਼ਨ

ਮੋਟਰ ਦੀ ਗਤੀ ਡਰਾਈਵਿੰਗ ਬਾਰੰਬਾਰਤਾ ਦੁਆਰਾ ਨਿਰਧਾਰਤ ਕੀਤੀ ਜਾਂਦੀ ਹੈ, ਅਤੇ ਇਸਦਾ ਲੋਡ ਨਾਲ ਕੋਈ ਲੈਣਾ-ਦੇਣਾ ਨਹੀਂ ਹੈ (ਜਦੋਂ ਤੱਕ ਕਿ ਇਹ ਕਦਮ ਗੁਆ ਰਹੀ ਹੋਵੇ)।

ਸਟੈਪਰ ਮੋਟਰਾਂ ਦੇ ਉੱਚ ਸ਼ੁੱਧਤਾ ਵਾਲੇ ਸਪੀਡ ਕੰਟਰੋਲ ਦੇ ਕਾਰਨ, ਡਰਾਈਵਰ ਦੁਆਰਾ ਨਿਯੰਤਰਿਤ ਸਟੈਪਿੰਗ ਨਾਲ ਤੁਸੀਂ ਬਹੁਤ ਹੀ ਸਟੀਕ ਸਥਿਤੀ ਅਤੇ ਗਤੀ ਨਿਯੰਤਰਣ ਪ੍ਰਾਪਤ ਕਰ ਸਕਦੇ ਹੋ। ਇਸ ਕਾਰਨ ਕਰਕੇ, ਸਟੈਪਰ ਮੋਟਰਾਂ ਬਹੁਤ ਸਾਰੇ ਸ਼ੁੱਧਤਾ ਵਾਲੇ ਮੋਸ਼ਨ ਕੰਟਰੋਲ ਐਪਲੀਕੇਸ਼ਨਾਂ ਲਈ ਪਸੰਦ ਦੀ ਮੋਟਰ ਹਨ।

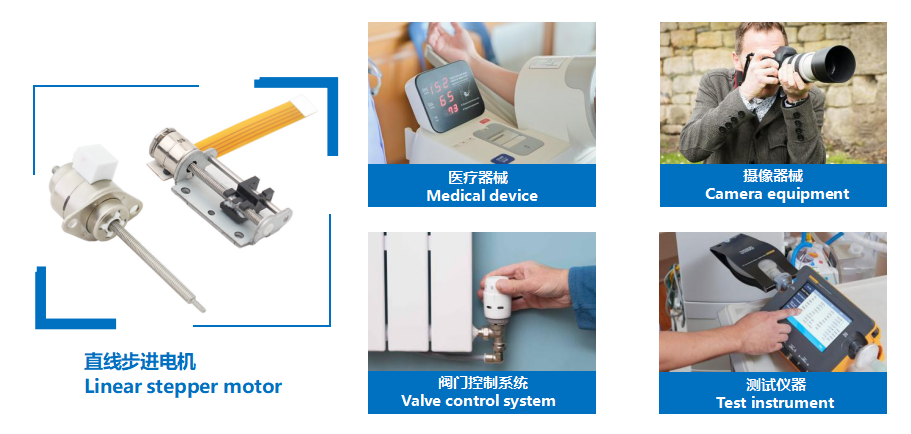

ਲੀਨੀਅਰ ਸਟੈਪਰ ਮੋਟਰਾਂ ਲਈ, ਇਹਨਾਂ ਦੀ ਵਿਆਪਕ ਵਰਤੋਂ ਇਹਨਾਂ ਵਿੱਚ ਕੀਤੀ ਜਾਂਦੀ ਹੈ:

ਮੈਡੀਕਲ ਡਿਵਾਈਸ

ਕੈਮਰਾ ਉਪਕਰਣ

ਵਾਲਵ ਕੰਟਰੋਲ ਸਿਸਟਮ

ਟੈਸਟ ਯੰਤਰ

3D ਪ੍ਰਿੰਟਿੰਗ

ਸੀਐਨਸੀ ਮਸ਼ੀਨ

ਇਤਆਦਿ

ਅਨੁਕੂਲਤਾ ਸੇਵਾ

ਮੋਟਰ ਦੇ ਡਿਜ਼ਾਈਨ ਨੂੰ ਗਾਹਕ ਦੀ ਜ਼ਰੂਰਤ ਦੇ ਅਧਾਰ ਤੇ ਐਡਜਸਟ ਕੀਤਾ ਜਾ ਸਕਦਾ ਹੈ ਜਿਸ ਵਿੱਚ ਸ਼ਾਮਲ ਹਨ:

ਮੋਟਰ ਦਾ ਵਿਆਸ: ਸਾਡੇ ਕੋਲ 6mm, 8mm, 10mm, 15mm ਅਤੇ 20mm ਵਿਆਸ ਵਾਲੀ ਮੋਟਰ ਹੈ।

ਕੋਇਲ ਪ੍ਰਤੀਰੋਧ/ਰੇਟਡ ਵੋਲਟੇਜ: ਕੋਇਲ ਪ੍ਰਤੀਰੋਧ ਵਿਵਸਥਿਤ ਹੁੰਦਾ ਹੈ, ਅਤੇ ਉੱਚ ਪ੍ਰਤੀਰੋਧ ਦੇ ਨਾਲ, ਮੋਟਰ ਦਾ ਰੇਟਡ ਵੋਲਟੇਜ ਵੱਧ ਹੁੰਦਾ ਹੈ।

ਬਰੈਕਟ ਡਿਜ਼ਾਈਨ/ਲੀਡ ਪੇਚ ਦੀ ਲੰਬਾਈ: ਜੇਕਰ ਗਾਹਕ ਚਾਹੁੰਦਾ ਹੈ ਕਿ ਬਰੈਕਟ ਲੰਬਾ/ਛੋਟਾ ਹੋਵੇ, ਖਾਸ ਡਿਜ਼ਾਈਨ ਜਿਵੇਂ ਕਿ ਮਾਊਂਟਿੰਗ ਹੋਲਜ਼ ਦੇ ਨਾਲ, ਤਾਂ ਇਹ ਐਡਜਸਟੇਬਲ ਹੈ।

PCB + ਕੇਬਲ + ਕਨੈਕਟਰ: PCB ਦਾ ਡਿਜ਼ਾਈਨ, ਕੇਬਲ ਦੀ ਲੰਬਾਈ ਅਤੇ ਕਨੈਕਟਰ ਪਿੱਚ ਸਾਰੇ ਐਡਜਸਟੇਬਲ ਹਨ, ਜੇਕਰ ਗਾਹਕਾਂ ਦੀ ਲੋੜ ਹੋਵੇ ਤਾਂ ਉਹਨਾਂ ਨੂੰ FPC ਵਿੱਚ ਬਦਲਿਆ ਜਾ ਸਕਦਾ ਹੈ।

ਲੀਡ ਟਾਈਮ ਅਤੇ ਪੈਕੇਜਿੰਗ ਜਾਣਕਾਰੀ

ਨਮੂਨਿਆਂ ਲਈ ਲੀਡ ਟਾਈਮ:

ਸਟਾਕ ਵਿੱਚ ਸਟੈਂਡਰਡ ਮੋਟਰਾਂ: 3 ਦਿਨਾਂ ਦੇ ਅੰਦਰ

ਸਟੈਂਡਰਡ ਮੋਟਰਾਂ ਸਟਾਕ ਵਿੱਚ ਨਹੀਂ ਹਨ: 15 ਦਿਨਾਂ ਦੇ ਅੰਦਰ

ਅਨੁਕੂਲਿਤ ਉਤਪਾਦ: ਲਗਭਗ 25 ~ 30 ਦਿਨ (ਅਨੁਕੂਲਿਤ ਕਰਨ ਦੀ ਗੁੰਝਲਤਾ ਦੇ ਅਧਾਰ ਤੇ)

ਨਵਾਂ ਮੋਲਡ ਬਣਾਉਣ ਲਈ ਸਮਾਂ: ਆਮ ਤੌਰ 'ਤੇ ਲਗਭਗ 45 ਦਿਨ

ਵੱਡੇ ਪੱਧਰ 'ਤੇ ਉਤਪਾਦਨ ਲਈ ਲੀਡ ਟਾਈਮ: ਆਰਡਰ ਦੀ ਮਾਤਰਾ ਦੇ ਅਧਾਰ ਤੇ

ਪੈਕੇਜਿੰਗ:

ਨਮੂਨੇ ਫੋਮ ਸਪੰਜ ਵਿੱਚ ਇੱਕ ਕਾਗਜ਼ ਦੇ ਡੱਬੇ ਨਾਲ ਪੈਕ ਕੀਤੇ ਜਾਂਦੇ ਹਨ, ਐਕਸਪ੍ਰੈਸ ਦੁਆਰਾ ਭੇਜੇ ਜਾਂਦੇ ਹਨ।

ਵੱਡੇ ਪੱਧਰ 'ਤੇ ਉਤਪਾਦਨ, ਮੋਟਰਾਂ ਨੂੰ ਬਾਹਰ ਪਾਰਦਰਸ਼ੀ ਫਿਲਮ ਦੇ ਨਾਲ ਨਾਲੀਦਾਰ ਡੱਬਿਆਂ ਵਿੱਚ ਪੈਕ ਕੀਤਾ ਜਾਂਦਾ ਹੈ। (ਹਵਾਈ ਰਾਹੀਂ ਸ਼ਿਪਿੰਗ)

ਜੇਕਰ ਸਮੁੰਦਰ ਰਾਹੀਂ ਭੇਜਿਆ ਜਾਂਦਾ ਹੈ, ਤਾਂ ਉਤਪਾਦ ਪੈਲੇਟਾਂ 'ਤੇ ਪੈਕ ਕੀਤਾ ਜਾਵੇਗਾ।

ਸ਼ਿਪਿੰਗ ਵਿਧੀ

ਨਮੂਨਿਆਂ ਅਤੇ ਹਵਾਈ ਸ਼ਿਪਿੰਗ 'ਤੇ, ਅਸੀਂ Fedex/TNT/UPS/DHL ਦੀ ਵਰਤੋਂ ਕਰਦੇ ਹਾਂ।(ਐਕਸਪ੍ਰੈਸ ਸੇਵਾ ਲਈ 5~12 ਦਿਨ)

ਸਮੁੰਦਰੀ ਜਹਾਜ਼ਾਂ ਲਈ, ਅਸੀਂ ਆਪਣੇ ਸ਼ਿਪਿੰਗ ਏਜੰਟ ਦੀ ਵਰਤੋਂ ਕਰਦੇ ਹਾਂ, ਅਤੇ ਸ਼ੰਘਾਈ ਬੰਦਰਗਾਹ ਤੋਂ ਜਹਾਜ਼ ਭੇਜਦੇ ਹਾਂ।(ਸਮੁੰਦਰੀ ਸ਼ਿਪਿੰਗ ਲਈ 45 ~ 70 ਦਿਨ)

ਅਕਸਰ ਪੁੱਛੇ ਜਾਂਦੇ ਸਵਾਲ

1. ਕੀ ਤੁਸੀਂ ਇੱਕ ਨਿਰਮਾਤਾ ਹੋ?

ਹਾਂ, ਅਸੀਂ ਇੱਕ ਨਿਰਮਾਤਾ ਹਾਂ, ਅਤੇ ਅਸੀਂ ਮੁੱਖ ਤੌਰ 'ਤੇ ਸਟੈਪਰ ਮੋਟਰਾਂ ਦਾ ਉਤਪਾਦਨ ਕਰਦੇ ਹਾਂ।

2. ਤੁਹਾਡੀ ਫੈਕਟਰੀ ਕਿੱਥੇ ਹੈ?ਕੀ ਅਸੀਂ ਤੁਹਾਡੀ ਫੈਕਟਰੀ ਦਾ ਦੌਰਾ ਕਰ ਸਕਦੇ ਹਾਂ?

ਸਾਡੀ ਫੈਕਟਰੀ ਚਾਂਗਜ਼ੂ, ਜਿਆਂਗਸੂ ਵਿੱਚ ਸਥਿਤ ਹੈ। ਹਾਂ, ਤੁਹਾਡਾ ਸਾਡੇ ਕੋਲ ਆਉਣ ਲਈ ਬਹੁਤ ਸਵਾਗਤ ਹੈ।

3. ਕੀ ਤੁਸੀਂ ਮੁਫ਼ਤ ਨਮੂਨੇ ਪ੍ਰਦਾਨ ਕਰ ਸਕਦੇ ਹੋ?

ਨਹੀਂ, ਅਸੀਂ ਮੁਫ਼ਤ ਨਮੂਨੇ ਨਹੀਂ ਦਿੰਦੇ। ਗਾਹਕ ਮੁਫ਼ਤ ਨਮੂਨਿਆਂ ਨਾਲ ਨਿਰਪੱਖ ਵਿਵਹਾਰ ਨਹੀਂ ਕਰਨਗੇ।

4. ਸ਼ਿਪਿੰਗ ਲਾਗਤ ਕੌਣ ਅਦਾ ਕਰਦਾ ਹੈ? ਕੀ ਮੈਂ ਆਪਣਾ ਸ਼ਿਪਿੰਗ ਖਾਤਾ ਵਰਤ ਸਕਦਾ ਹਾਂ?

ਗਾਹਕ ਸ਼ਿਪਿੰਗ ਲਾਗਤ ਦਾ ਭੁਗਤਾਨ ਕਰਦੇ ਹਨ। ਅਸੀਂ ਤੁਹਾਨੂੰ ਸ਼ਿਪਿੰਗ ਲਾਗਤ ਦਾ ਹਵਾਲਾ ਦੇਵਾਂਗੇ।

ਜੇਕਰ ਤੁਹਾਨੂੰ ਲੱਗਦਾ ਹੈ ਕਿ ਤੁਹਾਡੇ ਕੋਲ ਸਸਤਾ/ਵਧੇਰੇ ਸੁਵਿਧਾਜਨਕ ਸ਼ਿਪਿੰਗ ਤਰੀਕਾ ਹੈ, ਤਾਂ ਅਸੀਂ ਤੁਹਾਡੇ ਸ਼ਿਪਿੰਗ ਖਾਤੇ ਦੀ ਵਰਤੋਂ ਕਰ ਸਕਦੇ ਹਾਂ।

5. ਤੁਸੀਂ MOQ ਕੀ ਹੋ? ਕੀ ਮੈਂ ਇੱਕ ਮੋਟਰ ਆਰਡਰ ਕਰ ਸਕਦਾ ਹਾਂ?

ਸਾਡੇ ਕੋਲ MOQ ਨਹੀਂ ਹੈ, ਅਤੇ ਤੁਸੀਂ ਸਿਰਫ਼ ਇੱਕ ਟੁਕੜੇ ਦਾ ਨਮੂਨਾ ਮੰਗਵਾ ਸਕਦੇ ਹੋ।

ਪਰ ਅਸੀਂ ਤੁਹਾਨੂੰ ਥੋੜ੍ਹਾ ਹੋਰ ਆਰਡਰ ਕਰਨ ਦੀ ਸਿਫ਼ਾਰਸ਼ ਕਰਦੇ ਹਾਂ, ਸਿਰਫ਼ ਇਸ ਲਈ ਕਿ ਜੇਕਰ ਤੁਹਾਡੀ ਜਾਂਚ ਦੌਰਾਨ ਮੋਟਰ ਖਰਾਬ ਹੋ ਜਾਵੇ, ਅਤੇ ਤੁਸੀਂ ਬੈਕ-ਅੱਪ ਲੈ ਸਕਦੇ ਹੋ।

6. ਅਸੀਂ ਇੱਕ ਨਵਾਂ ਪ੍ਰੋਜੈਕਟ ਵਿਕਸਤ ਕਰ ਰਹੇ ਹਾਂ, ਕੀ ਤੁਸੀਂ ਕਸਟਮਾਈਜ਼ੇਸ਼ਨ ਸੇਵਾ ਪ੍ਰਦਾਨ ਕਰਦੇ ਹੋ? ਕੀ ਅਸੀਂ NDA ਇਕਰਾਰਨਾਮੇ 'ਤੇ ਦਸਤਖਤ ਕਰ ਸਕਦੇ ਹਾਂ?

ਸਾਡੇ ਕੋਲ ਸਟੈਪਰ ਮੋਟਰ ਉਦਯੋਗ ਵਿੱਚ 20 ਸਾਲਾਂ ਤੋਂ ਵੱਧ ਦਾ ਤਜਰਬਾ ਹੈ।

ਅਸੀਂ ਬਹੁਤ ਸਾਰੇ ਪ੍ਰੋਜੈਕਟ ਵਿਕਸਤ ਕੀਤੇ ਹਨ, ਅਸੀਂ ਡਿਜ਼ਾਈਨ ਡਰਾਇੰਗ ਤੋਂ ਲੈ ਕੇ ਉਤਪਾਦਨ ਤੱਕ ਪੂਰਾ ਸੈੱਟ ਅਨੁਕੂਲਤਾ ਪ੍ਰਦਾਨ ਕਰ ਸਕਦੇ ਹਾਂ।

ਸਾਨੂੰ ਭਰੋਸਾ ਹੈ ਕਿ ਅਸੀਂ ਤੁਹਾਡੇ ਸਟੈਪਰ ਮੋਟਰ ਪ੍ਰੋਜੈਕਟ ਲਈ ਤੁਹਾਨੂੰ ਕੁਝ ਸਲਾਹ/ਸੁਝਾਅ ਦੇ ਸਕਦੇ ਹਾਂ।

ਜੇਕਰ ਤੁਸੀਂ ਗੁਪਤ ਮੁੱਦਿਆਂ ਬਾਰੇ ਚਿੰਤਤ ਹੋ, ਤਾਂ ਹਾਂ, ਅਸੀਂ ਇੱਕ NDA ਇਕਰਾਰਨਾਮੇ 'ਤੇ ਦਸਤਖਤ ਕਰ ਸਕਦੇ ਹਾਂ।

7. ਕੀ ਤੁਸੀਂ ਡਰਾਈਵਰ ਵੇਚਦੇ ਹੋ? ਕੀ ਤੁਸੀਂ ਉਨ੍ਹਾਂ ਦਾ ਉਤਪਾਦਨ ਕਰਦੇ ਹੋ?

ਹਾਂ, ਅਸੀਂ ਡਰਾਈਵਰ ਵੇਚਦੇ ਹਾਂ। ਉਹ ਸਿਰਫ਼ ਅਸਥਾਈ ਨਮੂਨਾ ਟੈਸਟ ਲਈ ਢੁਕਵੇਂ ਹਨ, ਵੱਡੇ ਪੱਧਰ 'ਤੇ ਉਤਪਾਦਨ ਲਈ ਢੁਕਵੇਂ ਨਹੀਂ ਹਨ।

ਅਸੀਂ ਡਰਾਈਵਰ ਨਹੀਂ ਬਣਾਉਂਦੇ, ਅਸੀਂ ਸਿਰਫ਼ ਸਟੈਪਰ ਮੋਟਰਾਂ ਬਣਾਉਂਦੇ ਹਾਂ।